What is a Rigid Coupling?

Shaft Couplings serve as components to time, join, or align shafts at lower speeds and torque, especially when zero backlash is desired. They are not intended for use as a critical part of a drive line or as a substitute for flexible or universal joints or other power transmission devices. Rigid couplings are designed for aligned shafts only, and are the most basic but often the most cost-effective coupling.

For more information check out the following: Rigid Couplings Infographic:

What type of rigid coupling does Climax manufacture?

Climax manufactures rigid set screw couplings and rigid clamping couplings. We also offer customized dimensions, specialized plating and manufacture from a variety of materials.

Set Screw Couplings are secured to the shaft by set screws that impinge upon the shaft. Set screw couplings are also available with a keyway for keyed shafts.

Clamp Couplings are designed in a one-piece and (more…)

What materials are used in manufacturing Climax rigid couplings?

Steel Couplings are the most commonly used and manufactured. The exact type of steel used varies depending on the machine process but generally low-carbon steel is used, including materials such as 1215, 1045, and 1026.

Stainless Steel Couplings are used primarily in applications (more…)

What finishes does Climax offer on rigid couplings?

Black oxide finish on our steel couplings is formulated as part of the total performance of the coupling. The black oxide affects the anti-stick-slip characteristics and helps keep the torque rating of the screw within its design parameters. The black oxide has corrosion resistant properties for indoor environmental applications. However, black oxide (more…)

Why is a cross-cut on a coupling important?

A cross-cut is a lateral cut made halfway through the coupling. It is added to our one-piece and two-piece clamping couplings only. Similar to a relief cut, the cross-cut allows more tolerance for different size shafts. The cross-cut will help the rigid coupling clamp more securely and transmit power more efficiently even with these slight variations.

What is the Proper Technique for Opening the Bore on a Re-Machinable Coupling?

When opening the R2CC-Series bore:

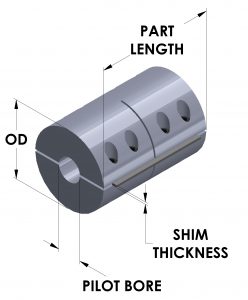

1. Start by inserting a shim in the saw cuts on both sides of the coupling as illustrated . Shim thickness is provided in the chart below.

| PILOT BORE (in) | MAX BORE (in) | OD (in) | PART LENGTH (in) | SHIM THICKNESS (in) |

| 1/4 | 3/4 | 1-3/4 | 2-5/8 | 0.093 |

| 1/2 | 1 | 2 | 3 | 0.093 |

| 3/4 | 1-1/2 | 2-1/2 | 3-3/4 | 0.093 |

| 1 | 2 | 3-1/4 | 4-7/8 | 0.093 |

2. Tighten the clamp screws so that the coupling clamps down on the shims.

3. The coupling bore is then machined with the installation screws tightened and the shims on both sides holding the two halves of the coupling apart.

For a printable version of these instructions, please click here: R2CC Proper Re-machining Instructions.