Keyless Rigid Moment Couplings Ensure Connection in Agriculture Conveying Equipment

Climax C600-Series Keyless Rigid Moment Couplings provide a superior solution for hydraulic motors and gearboxes over traditional misalignment couplings in agriculture applications.

Combine Harvesters Incorporate Conveyor Belts

When it’s time to harvest mature crop growth, combine harvesters are the most commonly used harvesting equipment by farmers. With an expected annual growth rate of 8.2% through 2030, combine harvesters are equipped with multiple conveyor belts that facilitate the reaping, threshing, and winnowing required during the harvesting process. Traditional methods for mounting hydraulic motors and gearboxes in conveyor applications often incorporate misalignment couplings that require frequent servicing. This potential failure can lead to downtime, negatively impacting production and profitability.

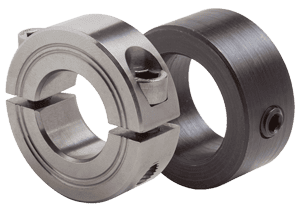

Stainless Steel Shaft Collars Superior for Demanding Food Processing Environments

Shaft collars manufactured from T316 stainless steel targets rust contamination issues found in hostile environments where frequent wash-downs are common and costly.

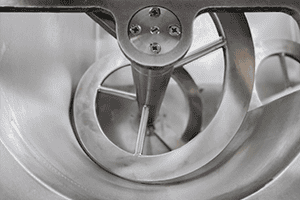

Paddle Mixers Used in Baking Applications

In the Baking Industry and general food processing environments, contamination from metal corrosion is a significant issue that many manufacturers face. In baking applications, the main sources of metal corrosion are the extremely harsh wash down environments, the use of highly corrosive cleaning and sanitation products, and the near-constant humid atmospheres within processing facilities. Equipment manufacturers are consistently tasked with selecting materials for machinery capable of withstanding these conditions. Once rust and corrosion occur, eradicating them from processing facilities becomes a time-consuming and costly process. Carefully designed equipment and utilizing components manufactured from adequately corrosion-resistant materials, contamination can be kept to a minimum.

Reliable Connection for Vibrating Applications in the Recycling Industry

Climax Keyless Locking Devices offer a superior solution to traditional keyed connections in screeners and vibrating conveyor applications commonly found in recycling facilities.

Conveyors Utilized in Recycling Applications

The recycling industry relies on heavy machinery, such as vibrating conveyors and screeners, to transport and sort materials. These machines require a strong shaft/hub connection capable of handling high torque due to constant motion and vibration. Vibratory machines often use keyed connections, which can reduce shaft strength by up to 30%, making the shaft more vulnerable to torsional and bending stresses. Additionally, when set screws are used to secure components on a shaft, marring can occur. The small oscillatory movements and vibrations make these machines susceptible to keyway fretting, causing gradual erosion over time.

Custom Designed Solution for Roller Coaster Lap Bar Applications

In the dynamic world of amusement park engineering, Climax Keyless Locking Devices provide design engineers with the flexibility necessary to navigate even the most challenging obstacles in the industry.

In today’s dynamic market, the global amusement park industry stands as an economic force, with a value just shy of $64 billion US dollars. Forecasts predict substantial growth in the years ahead, solidifying its position in the entertainment sector. The relentless appeal of whirling attractions and the delighted screams of guests spanning all ages present park owners with an excess of unique challenges to navigate. At the forefront of concerns lies the drive to craft unforgettable experiences, deliver cutting-edge attractions, and uphold the highest of standards of safety and integrity for riders.

In today’s dynamic market, the global amusement park industry stands as an economic force, with a value just shy of $64 billion US dollars. Forecasts predict substantial growth in the years ahead, solidifying its position in the entertainment sector. The relentless appeal of whirling attractions and the delighted screams of guests spanning all ages present park owners with an excess of unique challenges to navigate. At the forefront of concerns lies the drive to craft unforgettable experiences, deliver cutting-edge attractions, and uphold the highest of standards of safety and integrity for riders.

These expectations have spurred a demand for (more…)

Semiconductor Manufacturing Industry Requires Positional Accuracy & Repeatability

Climax Keyless Locking Devices provide a reliable solution when connecting drive line components in high-speed index packaging machinery commonly used in the semiconductor manufacturing industry.

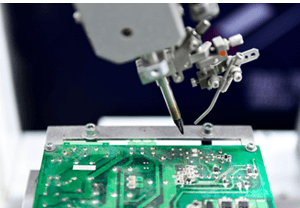

Semiconductor Manufacturing

As the demand for semiconductors and associated components continues to rise, high-speed index machinery needs to operate at peak efficiency. Increased production is essential, putting a great deal of strain on manufacturing equipment. The drive line components, in particular, need to maintain positional accuracy and repeatability. Unfortunately, keyed connections can wear out, become out of sync, or break down, causing excessive downtime and loss of productivity.

The semiconductor manufacturing industry is one that relies heavily on the positional accuracy of its machinery, making a reliable shaft connection vital. Climax Keyless Locking Devices (KLDs) are an excellent solution for (more…)

Superior Connection for Vertical Scrubbers Found in Automated Car Wash Systems

Climax Keyless Rigid Moment Couplings provide a superior connection solution for vertical scrubbers, eliminating problems associated with traditional keyed methods.

Vertical Brush Application in Car Wash Systems

Cloth-friction wash systems, popular in automated car wash facilities, incorporate the use of soft cloths or brushes. As the vehicle moves through the car wash tunnel, these soft cloths or brushes move around the exterior surface of the vehicle, eliminating unwanted dirt and debris.

This cloth-friction wash system incorporates design features where large vertical mechanisms called scrubbers have multiple cloth strips attached to them. These scrubbers rotate at a very high speed, spinning the cloth strips as they encounter the sides and top of the vehicle while it moves past the scrubbers. The cloths are soft, but since they spin at a high rate of speed, (more…)

Custom Designed Two-Piece Couplings Offer a Superior Solution for Line Shafts

Climax Two-Piece Clamping Couplings provide a superior solution for line shaft failed components, saving countless hours of downtime and increasing productivity.

Climax Custom Designed Coupling

Line shafts are an essential element in the power transmission industry and are used primarily to synchronize multiple components on equipment. Line shafts are common in many industries, including Timber, Forestry, Food Processing, Glass Production, Bottling, and Mills.

Recently, a customer was faced with a challenge where a one-piece tapered bushing used to mount several lever arms onto a line shaft continued to fail. As a result of using a one-piece tapered bushing, maintenance was tasked with the tedious process of removing all other components mounted between the bushing and the egress point. This removal process was often labor-intensive and required extended downtime, resulting in a loss of profits and productivity.

Climax’s knowledgeable engineering team, in collaboration with the customer, designed a two-piece clamping coupling with a welded lever arm as a solution to the customer’s problem. The two-piece clamping coupling was designed with sufficient torque and axial load capacity to address the failure issue faced by the customer. Additionally, the use of a (more…)

Large Bore Couplings Provide Solution for Line Shaft Timber Applications

Climax Large Bore Two-Piece Clamping Couplings provide a stronger and more efficient connection over antiquated approaches in timbering applications especially useful for transmitting higher loads required for line shafts.

From the initial harvesting of timber to the production of final goods, machinery used in forestry, particularly in sawmill applications, faces some of the most severe conditions and demanding loads imaginable. In this challenging environment, engineers design equipment to withstand rigorous use and harsh elements. Among the various types of couplings utilized in the timber industry, rigid couplings stand out as the true workhorses of the coupling family. Ideal for numerous line shaft applications, rigid couplings play a vital role in ensuring the efficiency and reliability of machinery throughout the timber processing chain.

Climax’s state of the art facility, located in Mentor, Ohio, manufactures couplings with imperial bore sizes up to 4 7/16 inches and metric sizes up to 75mm, with the flexibility to accommodate larger sizes based on specific applications. Climax offers a comprehensive line of rigid couplings, available in set screw, one-piece, and two-piece styles, with or without keyways. Our balanced couplings (more…)

Expanded Metric Offering Provides Necessary Sizes for the Food & Beverage Industries

Climax now provides an extended metric size offering in two-piece and set-screw shaft collars styles with bore sizes up to 150mm. This extended offering from stock allows for quick access to larger sizes when needed.

In food processing and bottling applications, processing equipment is subjected to some of the harshest environments possible. Preventative maintenance is a critical step, ensuring that the production line is operating at optimal performance limiting downtime and loss in productivity. Shaft collars provide a vital function and assist in locking or spacing components on a shaft. These silent warriors are often replaced during maintenance cycles to ensure they maintain their holding power.

(more…)Superior Solution for Shaft Connections in Large Bore Applications

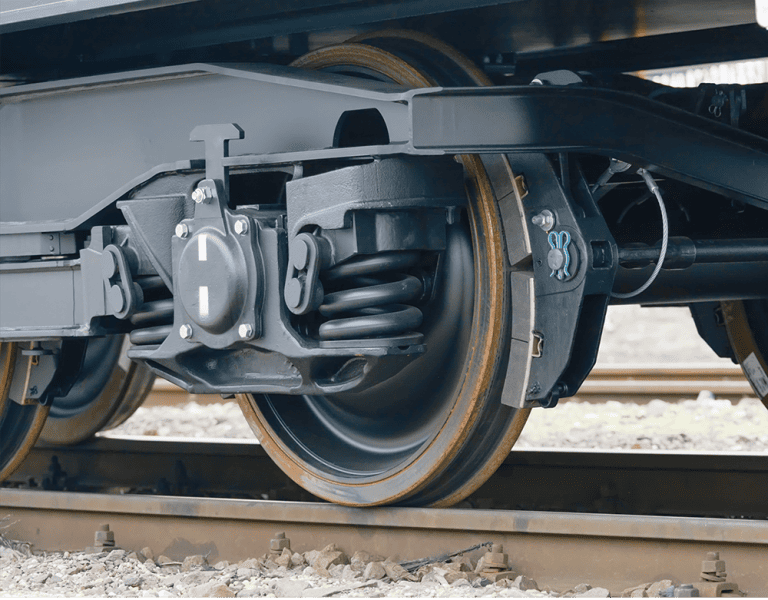

Traditional large cast iron couplings, commonly utilized to connect shafts in various heavy-duty applications such as lumber, steel, rail, recycling, and paper industries, are typically manufactured from iron and are known for their substantial weight.

Conventional large cast iron couplings feature a bulky design, necessitating extra space to accommodate their oversized outer diameter. The sheer size of these antiquated couplings places undue stress on the shaft and increases the risk of damaging both the shaft and its associated components. Likewise, to achieve the necessary torque for these applications, cast iron couplings rely on a keyway, leading to issues such as wallowing, backlash, fretting corrosion, and fatigue failure, all commonly associated with keyways.