Maintaining Component Integrity in Wastewater Treatment Plants

Climax Shrink Disc style flanged couplings in lieu of bore-keyway-setscrew or interference fits, allows for stronger shafts while eliminating corrosion sites and stress risers that are a common point of failure.

Using a press or shrink fit method, while effective (more…)

Eliminate Unnecessary Downtime in Asphalt Mixing Plants

Climax Keyless Locking Assemblies facilitate the repair and rebuild of rotary asphalt plant trunnions providing a cost-effective and maintenance-friendly alternative to the traditional sweat fit methods.

The loss of productivity during this often lengthy (more…)

Productivity Solutions for Food Processing

Climax C600 Series Keyless Rigid Couplings provide a superior cost-effective method to mount motors and gearboxes over traditional approaches in food processing applications.

Even when these components are properly aligned these connections are subjected to outside elements that can affect alignment. Climax Keyless Rigid Couplings are easy to install with simple hand tools, eliminating the need for brackets and expensive structure to support the motor, as well as installation misalignment. They contain no flexible elements saving maintenance costs and subsequent downtime. Torque mounting ensures that shafts are in perfect alignment, and C600s provide high torque (more…)

Keyless Locking Devices Eliminate the Need for Keyways in the Oil & Gas Industry

Climax Keyless Locking Devices used in place of keyways when mounting shaft components for manufacturing cold rolled steel and welded pipes eliminate fretting and associated equipment damage.

Climax Metal Products decided to look for alternate solutions to prevent keyway failures. Climax Series C600 Keyless Rigid Couplings with a step-bore inner ring provides this solution. A Climax Keyless Rigid Coupling creates a high pressure high capacity mechanical interference fit that eliminates the “slop” from the connection while providing the reassurance that a keyway failure is avoided. Additionally, the zero backlash connection is unaffected by (more…)

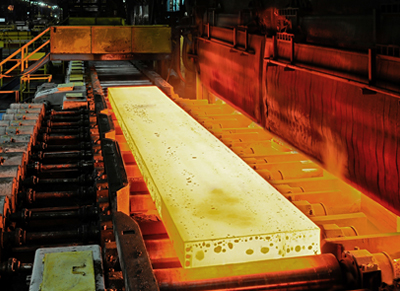

Timing Solutions for Steel Mill Production Lines

Climax Keyless Locking Assemblies provide timing solutions for steel mill production lines providing a cost-effective and maintenance-friendly alternative to traditional keyed connections.

The hot rolled bar production line in a steel mill has gears in the transfer station for lifting the hot metal bars. These gear/lifting arm combinations demand strict sync tolerances in order for the transfer process to run smoothly. Eventually as these arms pick up and transfer large quantities of very long steel bars, the keyed connection is compromised, causing the lifting arms to lose synchronization and production to be halted. This need to periodically re-align the gears and/or replace expensive keyed shafting is often very expensive, difficult, and time consuming. (more…)