Rigid Couplings Consistently Deliver Precise Alignment Screw Conveyors Require

In grain harvesting and production systems, screw conveyors require precise shaft alignment to ensure optimal torque transmission, maximized system efficiency, and maintain consistent material flow throughout the process.

Climax Rigid Couplings are the true workhorse of the coupling family. Rigid couplings provide a precise shaft alignment and torque transmission in applications where no relative movement between shafts is required. A simple, solid construction makes them ideal for high-torque, low-speed systems. Delivering a maintenance-free, robust solution for connecting drive shafts to screw shafts, rigid couplings are ideal for demanding grain-handling environments. (more…)

Eliminate Timing Drift & Mechanical Failure in High-Volume Print Operations

Mechanical connection failures common to the printing industry can significantly disrupt system performance, positional accuracy, and overall print quality.

High-Volume Print Applications

In high-volume print industry machinery, synchronized multi-stage operations are essential for minimizing cycle times and maximizing production efficiency. Traditional keyed shaft-to-hub connections are common but are prone to mechanical breakdowns under repetitive load cycles and dynamic torque conditions.

Over time, keyways can develop backlash, leading to misalignment, timing drift, and eventual mechanical failure. This connection deterioration can undermine synchronization between stages, resulting in print defects and unplanned downtime.

Keyless Locking Devices Provide Reliable Connections for Plastic Extrusion Equipment

Climax Keyless Locking Devices eliminate the use of keyed connections on plastic extrusion machinery while delivering enhanced longevity, reliability, and performance.

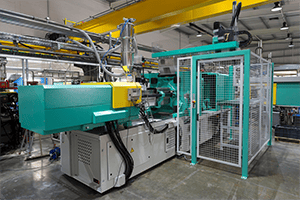

Plastic Extrusion Equipment Requires Reliable Connection

The global market for extrusion machinery is set to grow 4.5% annually by 2030. Plastics leads the industry, driving 77.2% of total revenue. This growth is driven by a rising demand across various sectors and a stronger push towards sustainability.

In high-pressure plastics manufacturing, high-torque injection molding machines are the industry standard. These machines face strenuous demands, particularly when maintaining positional accuracy and repeatability across the driveline. Over time, traditional keyed connections can degrade under stress, leading to wear, backlash, and timing irregularities. To ensure long-term performance and safety, the plastic extrusion process necessitates a shaft-to-hub connection that is reliable, resists harsh environments, and maintains structural integrity. (more…)