Stainless Steel Shaft Collars Superior for Demanding Food Processing Environments

Shaft collars manufactured from T316 stainless steel targets rust contamination issues found in hostile environments where frequent wash-downs are common and costly.

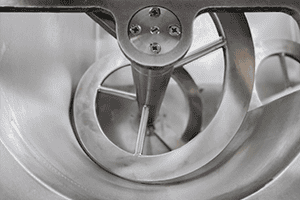

Paddle Mixers Used in Baking Applications

In the Baking Industry and general food processing environments, contamination from metal corrosion is a significant issue that many manufacturers face. In baking applications, the main sources of metal corrosion are the extremely harsh wash down environments, the use of highly corrosive cleaning and sanitation products, and the near-constant humid atmospheres within processing facilities. Equipment manufacturers are consistently tasked with selecting materials for machinery capable of withstanding these conditions. Once rust and corrosion occur, eradicating them from processing facilities becomes a time-consuming and costly process. Carefully designed equipment and utilizing components manufactured from adequately corrosion-resistant materials, contamination can be kept to a minimum.

Expanded Metric Offering Provides Necessary Sizes for the Food & Beverage Industries

Climax now provides an extended metric size offering in two-piece and set-screw shaft collars styles with bore sizes up to 150mm. This extended offering from stock allows for quick access to larger sizes when needed.

In food processing and bottling applications, processing equipment is subjected to some of the harshest environments possible. Preventative maintenance is a critical step, ensuring that the production line is operating at optimal performance limiting downtime and loss in productivity. Shaft collars provide a vital function and assist in locking or spacing components on a shaft. These silent warriors are often replaced during maintenance cycles to ensure they maintain their holding power.

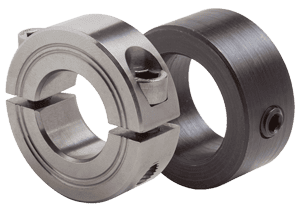

(more…)316 Stainless Steel Corrosion Resistant Shaft Collars

Climax 316 stainless steel shaft collars provide a locking solution that eliminates the likelihood of contamination from corrosion in environments where frequent wash-downs are common and downtime is costly.

Climax offers a solution to the corrosive environments persistent in many applications in the Food and Beverage Industry. Shaft collars manufactured from 316SS are extremely corrosion resistant making them ideal for applications in harsh environments. Since stainless steel is easy to sanitize, in inert to corrosion, and is proven durable, it is considered the industry standard for food processing, packaging, breweries, bottling, and canning applications.

Download our Corrosion Resistant Shaft Collars Brochure (PDF) or see our complete offering by product type below:

CR1C-Series One-Piece Clamping Collars

CR2C-Series Two-Piece Clamping Collars

Eliminating Problems Associated with Corrosion Contamination in the Beer & Ale Industry

Climax 316 stainless steel shaft collars provide for a locking solution that eliminates the likelihood of contamination from corrosion in an environment where frequent wash-downs are common and downtime is costly.

At the end of 2017 there were approximately 8,000 breweries in the United States according to America’s Beer Distributors website (nbwa.org). The estimated current market value of the beer industry is $114 billion dollars. As consumers continue to demand this popular beverage, breweries will need to maintain and replace equipment in order to keep up with production. Corrosion in breweries continues to prove challenging to this industry. Choosing the wrong metals can have an impact on flavor, can cause contamination in the product, and consequent downtime.

Corrosion Resistant Shaft Collars Provide a Solution to Hostile Environments

For more information on our complete line of corrosion resistant shaft collars, contact Climax at 800-542-6552 and ask how we can help.

For a printable version of this Industry Application click here: Corrosion Resistant Shaft Collars

Productivity Solutions for Food Processing

Climax C600 Series Keyless Rigid Couplings provide a superior cost-effective method to mount motors and gearboxes over traditional approaches in food processing applications.

Even when these components are properly aligned these connections are subjected to outside elements that can affect alignment. Climax Keyless Rigid Couplings are easy to install with simple hand tools, eliminating the need for brackets and expensive structure to support the motor, as well as installation misalignment. They contain no flexible elements saving maintenance costs and subsequent downtime. Torque mounting ensures that shafts are in perfect alignment, and C600s provide high torque (more…)