Optimal Solution for Mining Belt Conveyor Systems

Climax Keyless Locking Devices provide advantages over keyed connections. Mining OEMs incorporate keyless connections in equipment design.

Mining machinery is constantly subjected (more…)

Mining Shovels & Excavators Benefit From the Use of Climax KLDs

Climax Keyless Locking Devices offer an alternative for clumsy clevis pin retention and brake rotors in excavators and dragline shovels.

Construction machinery is constantly subjected to the harshest environments and toughest loads for which an engineer can design. Maintenance is an important factor in keeping costs down and ensuring that construction site progress stays on schedule. Moving parts are expected to wear out over time especially where (more…)

Mechanical Integrity Without Machining: KLD Solutions for Crusher Shaft Interfaces

Mining-grade crushing equipment can achieve greater mechanical integrity and simplified maintenance using Climax Keyless Locking Devices, which outperform conventional keyed connections.

KLD Ensures Integrity Without Machining

Jaw crushers widely used in the mining industry, often rely on costly press or sweat fits, or traditional keyed connections. However, these approaches often come with several drawbacks. Keyed shafts must be oversized to compensate for reduced effective cross-section, increasing weight and cost – not just for the shaft itself, but for every component mounted on it. Additionally, keyways are prone to fretting corrosion, backlash, and are incapable of transmitting bending moments or axial loads.

Impact crushers incorporating interference-fit rotor-to-shaft connections require precision machining, specialized fixturing, high-capacity hydraulic presses, and substantial labor investment during assembly. Climax heavy-duty locking assemblies, such as the C405-Series, achieve the same mechanical integrity of interference fits while significantly reducing manufacturing complexity and cost, with a simplified machining investment. Additionally, these locking assemblies provide a robust solution for mounting drive sheaves, effectively eliminating the drawbacks associated with keyed connections – including fretting, backlash, and limited load transmission, as well as belt misalignment issues inherent to QD or XT bushings.

Maintaining Component Integrity in Wastewater Treatment Plants

Climax Shrink Disc style flanged couplings in lieu of bore-keyway-setscrew or interference fits, allows for stronger shafts while eliminating corrosion sites and stress risers that are a common point of failure.

Using a press or shrink fit method, while effective (more…)

Enhancing Operational Efficiency in Drum Rotation Systems in Asphalt Production Facilities

Climax Keyless Locking Assemblies provide an alternative method for assembling rotary trunnions in asphalt plants, replacing traditional sweat-fit techniques with a more serviceable and mechanically efficient solutions.

Asphalt production facilities utilize a series of trunnion assemblies to support and rotate drums containing heated asphalt mix. Traditionally, trunnion wheels are either machined from a single forged steel billet to exact dimensions or, more commonly, made using a “sweat fit” configuration. Using this “sweat fit” method, the axle is fitted between dual bearings and the mounted wheel, creating a rigid but maintenance-intensive assembly.

In the event of bearing failure or tire wear, the entire assembly requires disassembly for service. Due to the complexities of a sweat fit, separating the axle from the wheel is often difficult., necessitating elevated temperatures and the use of high-tonnage hydraulic presses, resulting in extended downtime and increased labor costs. (more…)

Productivity Solutions for Food Processing

Climax C600 Series Keyless Rigid Couplings provide a superior cost-effective method to mount motors and gearboxes over traditional approaches in food processing applications.

Even when these components are properly aligned these connections are subjected to outside elements that can affect alignment. Climax Keyless Rigid Couplings are easy to install with simple hand tools, eliminating the need for brackets and expensive structure to support the motor, as well as installation misalignment. They contain no flexible elements saving maintenance costs and subsequent downtime. Torque mounting ensures that shafts are in perfect alignment, and C600s provide high torque (more…)

Keyless Locking Devices Eliminate the Need for Keyways in the Oil & Gas Industry

Climax Keyless Locking Devices used in place of keyways when mounting shaft components for manufacturing cold rolled steel and welded pipes eliminate fretting and associated equipment damage.

Climax Metal Products decided to look for alternate solutions to prevent keyway failures. Climax Series C600 Keyless Rigid Couplings with a step-bore inner ring provides this solution. A Climax Keyless Rigid Coupling creates a high pressure high capacity mechanical interference fit that eliminates the “slop” from the connection while providing the reassurance that a keyway failure is avoided. Additionally, the zero backlash connection is unaffected by (more…)

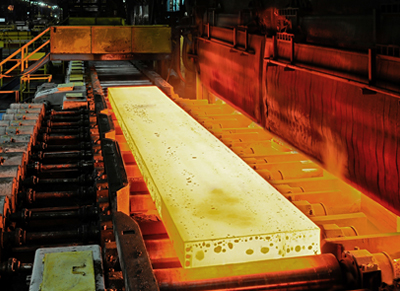

Timing Solutions for Steel Mill Production Lines

Climax Keyless Locking Assemblies provide timing solutions for steel mill production lines providing a cost-effective and maintenance-friendly alternative to traditional keyed connections.

The hot rolled bar production line in a steel mill has gears in the transfer station for lifting the hot metal bars. These gear/lifting arm combinations demand strict sync tolerances in order for the transfer process to run smoothly. Eventually as these arms pick up and transfer large quantities of very long steel bars, the keyed connection is compromised, causing the lifting arms to lose synchronization and production to be halted. This need to periodically re-align the gears and/or replace expensive keyed shafting is often very expensive, difficult, and time consuming. (more…)